Holistic design makes every part serve the whole.

Pumps are systems of interdependent parts—pressure boundaries, stators, rotors, bearings, and seals—that must be engineered holistically to perform effectively.

For decades, cost control drove designs toward standardization—shared bearing housings among product lines, standard pressure ratings for castings, and multiple impellers used in a single case. That approach reduced capital cost, but it often compromised performance and reliability when applied to demanding services. Components designed to serve “many machines” rarely met the exact hydraulic, thermal, or mechanical requirements of a given application.

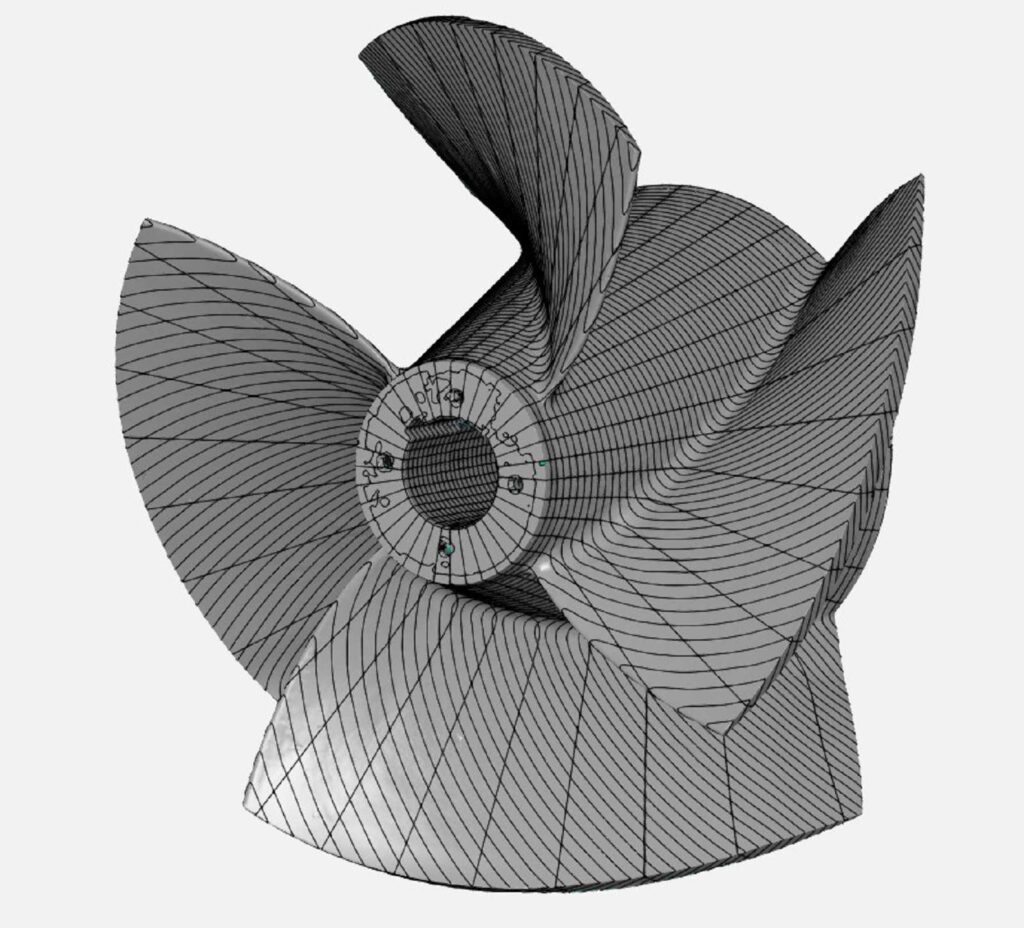

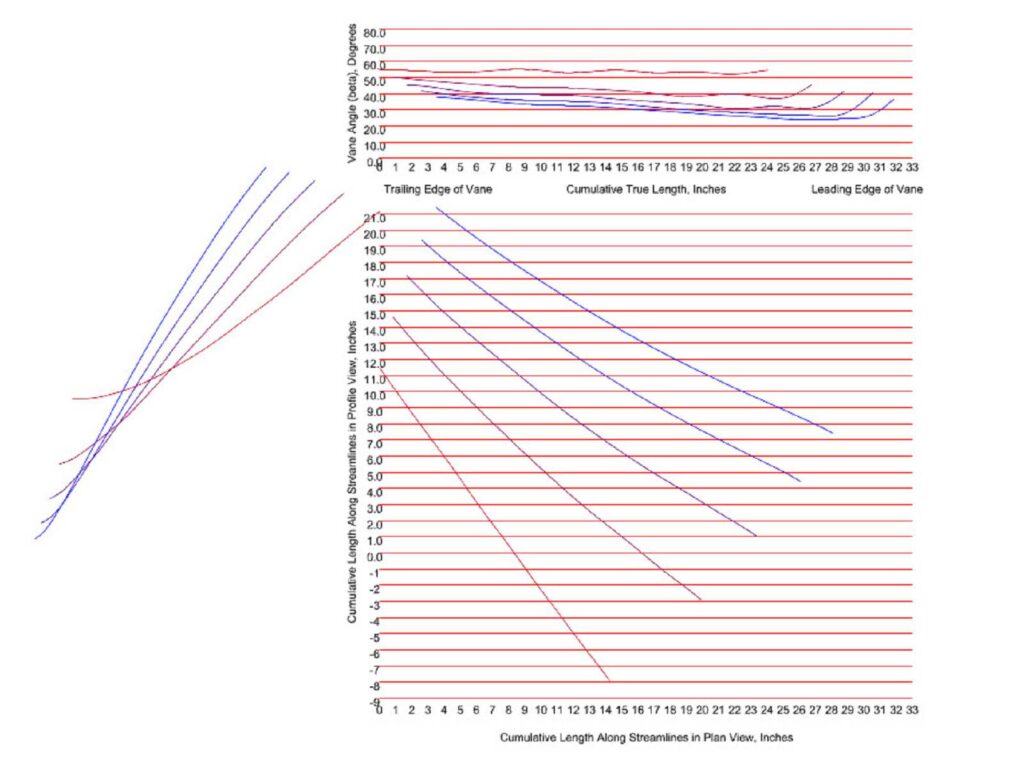

Today, advanced manufacturing methods remove many of those constraints. 3D-printed sand molds and CNC machining make application-specific components practical and cost-competitive. This enables a return to engineering-led design, where geometry, materials, and details are optimized for the actual service. Our experience with additive and subtractive processes—3D-printed cores, CNC machining, EDM—allows us to deliver components and pumps that do more than restore function; they solve recurring problems and extend service life.