Custom design without costly rework.

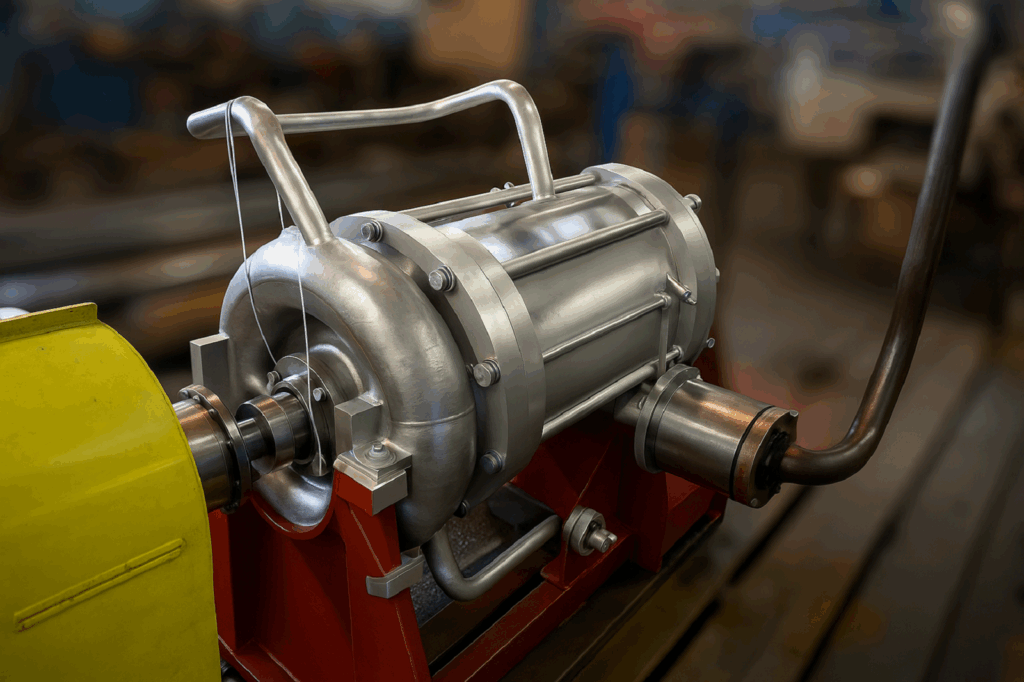

A drop-in replacement pump eliminates the cost and disruption of modifying piping, foundations, or drivers. We design pumps that fit the existing footprint while meeting current performance needs.

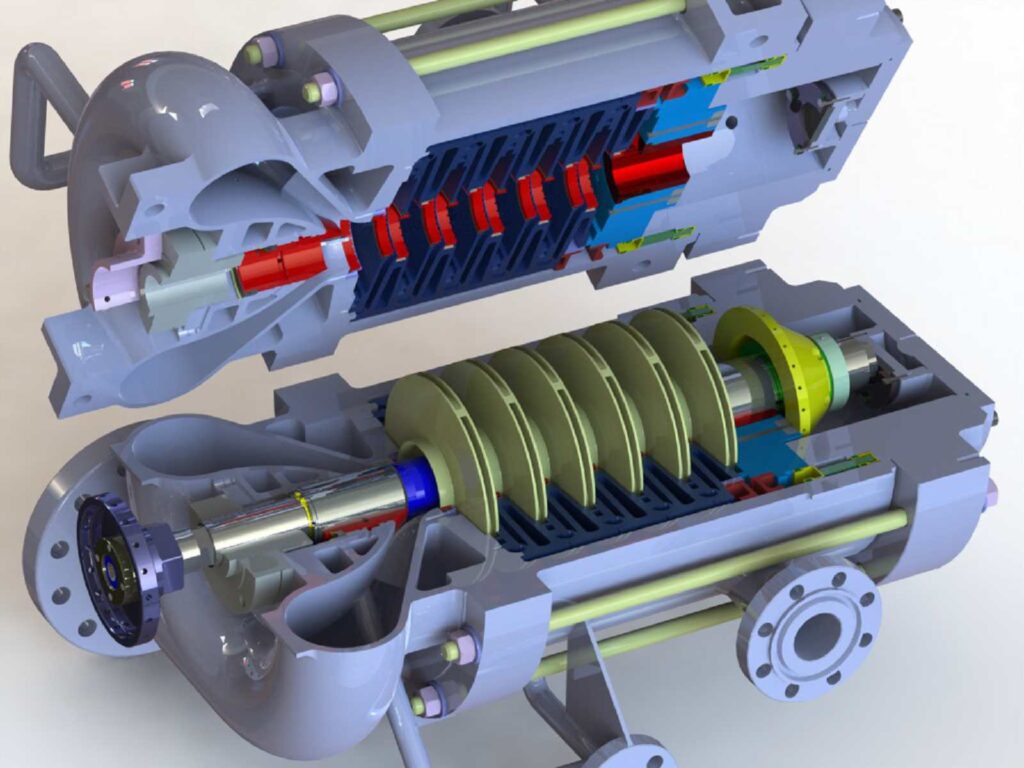

Where OEM outline drawings are incomplete or there have been prior modifications, we take site measurements to ensure dimensional accuracy. If additional driver power is required, we coordinate modifications—such as enlarging steam turbine nozzles, rewinding motors, or upgrading motor insulation—to support the increased load.

Often, the coupling spacer length must be increased to fill the gap created by shorter bearing spans. We can design couplings (hubs, and spacers) that require no maintenance.

The result is a solution tailored to the installation, providing reliability improvements and cost savings without the penalties of field rework. Case studies of successful drop-in replacements demonstrate how this approach delivers long-term value.