Transformed notorious ‘bad actor’ into a ‘bad memory’ with no baseplate, piping, or driver changes.

Key Metrics: In service since 2008 | Zero lost production | Zero overhauls | Three planned seal replacements

Client: Major Petroleum Refiner in USA

Service: Hydraulic and mechanical (including hydrostatic bearings) design, documentation, performance testing, installation and start-up supervision, training of plant personnel.

Scope: Engineering for a pump compliant with API 610, 10th edition, for 450°F service. Design an extended coupling and pedestal to fit the baseplate. Review laboratory performance tests and author a comprehensive Installation, Operation, and Maintenance Manual (IOM).

Highlights: Zero unplanned outages, no piping changes, customer owns electronic files of design calculations, detailed machine drawings, and IOM.

The Challenge

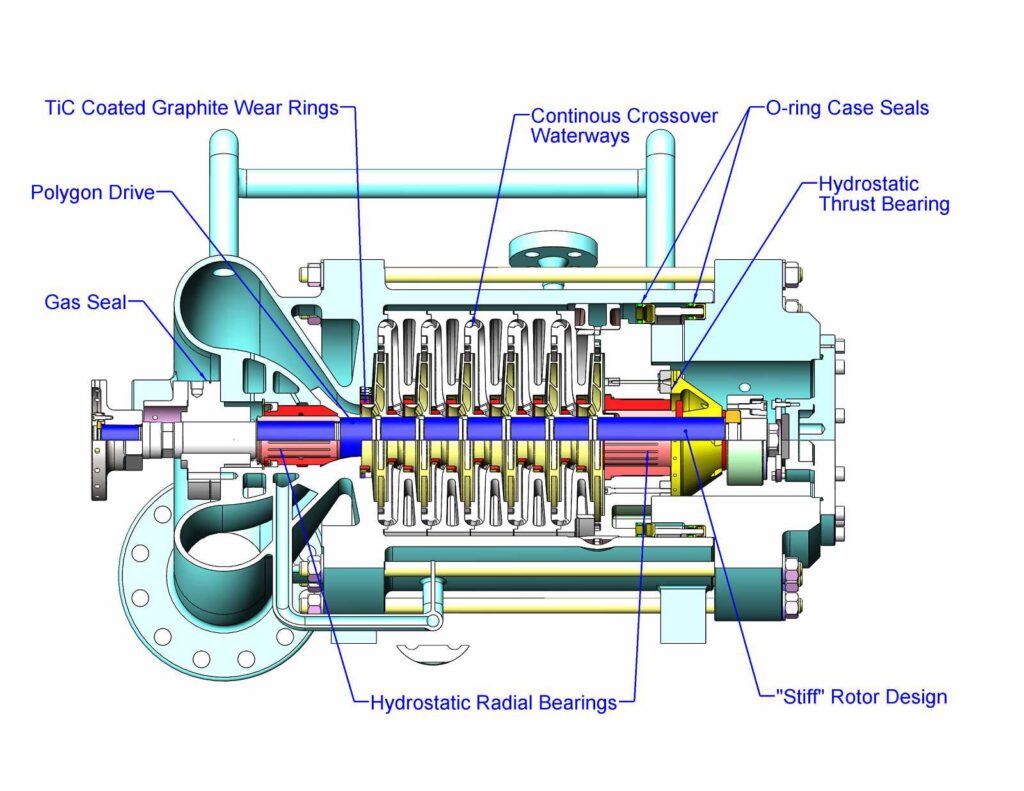

In refinery hot service at 450°F, the pump’s long rotor span and conventional seal system led to chronic failures. Mechanical seals failed every 5–6 months, and major overhauls were required every 18 months. Maintenance cycles were unsustainable, driving the need for a complete re-engineering effort.

Constraints

- Maintain existing baseplates, piping connections, and driver location

- Improve reliability with stiff rotor and exotic materials

- Validate design with hydraulic and mechanical tests

- Deliver vendor-agnostic drawings/specs

Our Approach

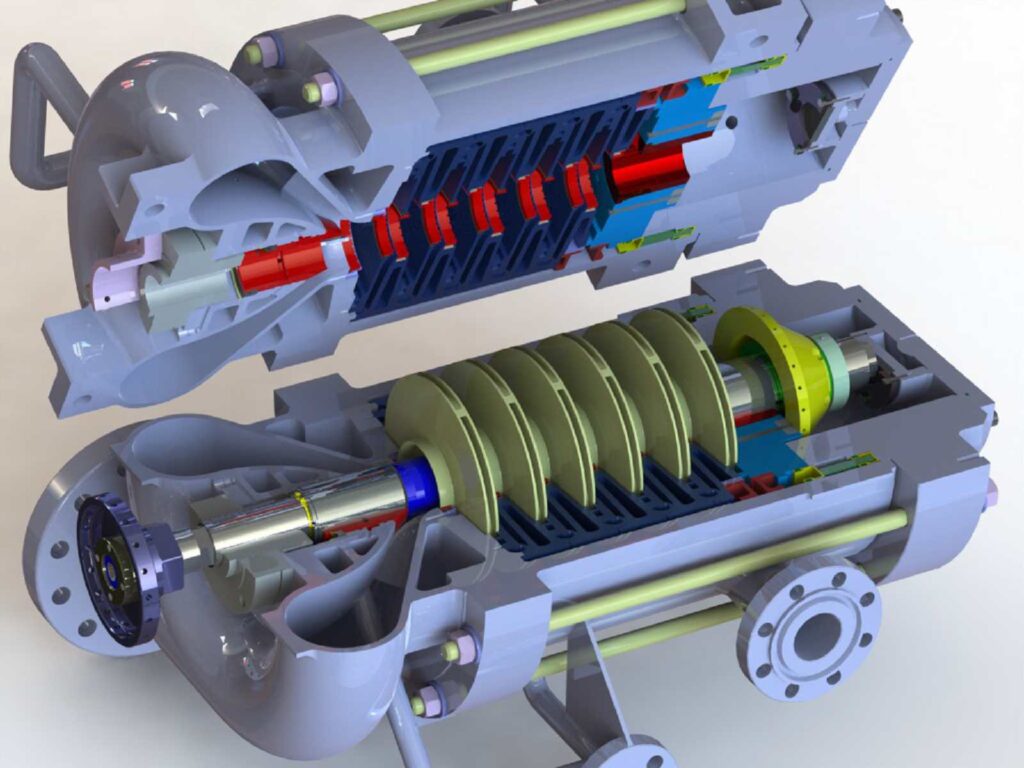

- Step 1: Build a 3D model of all physical constraints.

- Step 2: Develop an optimum hydraulic design to achieve the shortest distance between bearings.

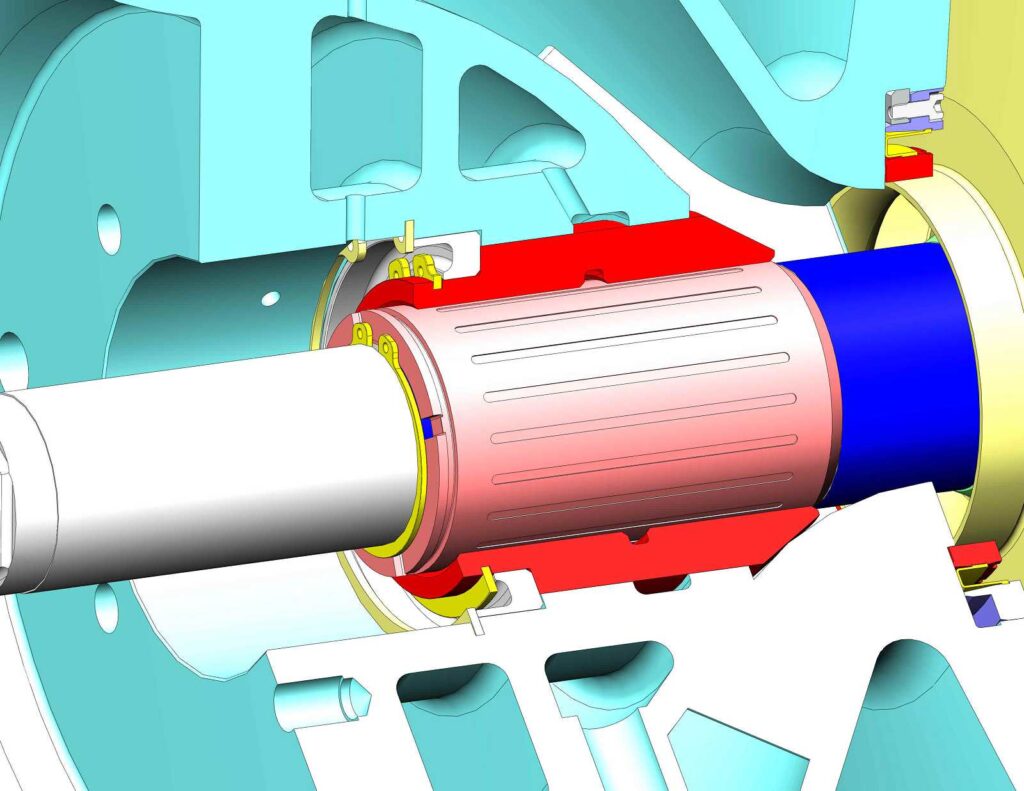

- Step 3: Integrate product-lubricated bearings for high-temperature reliability.

- Step 4: Package the hydraulic component and hydrostatic bearings in a pressure boundary with nozzle locations that fit into the 3D model of constraints.

Results & Impact

The redesigned pump bearing span was reduced from 72 inches to 22 inches, creating a classically ‘stiff’, stable rotor independent of wear ring bearing coefficients. Two conventional high-temperature mechanical seals were replaced with one gas seal; the non-drive end required no seal at all. Since commissioning in 2008, the pump has achieved zero unplanned outages, no refurbishments, and only three scheduled seal replacements. The refinery has experienced uninterrupted production with drastically reduced maintenance costs.

Deliverables

- Design calculations

- 3D CAD models

- Fully detailed manufacturing drawings

- Installation, Operation, and Maintenance Manual (IOM)

- Mechanical and hydraulic test results

Testimonial

The pump’s success impressed Heinz P. Bloch enough to become the cover image on his book “Pump Wisdom: Problem Solving for Operators and Specialists,” published in 2011.

Cross-Links

Related Projects: API Pump Retrofit for Hot Service; Boiler Feed Pump Case Replacement; Polygon Shafts